Sheet Moulding Compound (SMC) is a sheet-like, ready-to-use moulding compound. It consists of thermosetting reactive resin and short-cut glass fibers. Companies use SMC to produce stable and precise fiber composite plastics. The compound already contains all the necessary components: Resin matrix, reinforcing fibers, fillers and additives are homogeneously premixed.In contrast, shapeless variants that are not supplied as sheets are referred to as bulk moulding compounds (BMC).

During hot pressing, companies shape the SMC into finished molded parts under high temperatures and pressure. To do this, they use heated steel tools that are inserted into hydraulic presses. The temperature of the tools is usually above 120 °C.

The technology of hot pressing dates back to the 1920s. Even back then, companies were producing molded parts for electrotechnical applications on hand-operated presses. The Belgian-American chemist Leo Baekeland laid the foundations for this technology as early as 1907 with his “pressure-heat patent”. After the Second World War, the demand for thermosetting moulding compounds rose sharply. At first, bulk moulding compounds were mainly used, but from the 1960s onwards, sheet moulding compounds were also widely used in the industry.

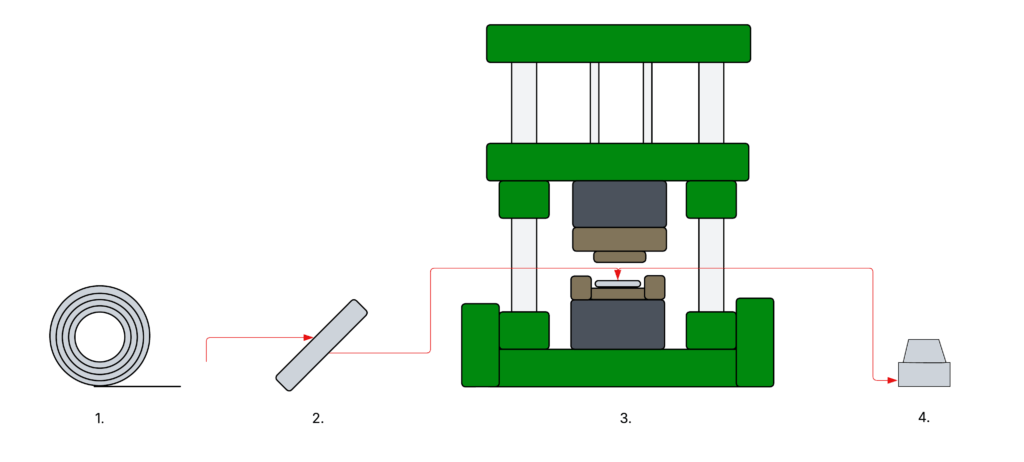

Process steps Hot pressing

SMC is cut into blanks for processing. These blanks are cut either mechanically on a cutting machine or manually on the press. The SMC blanks are usually smaller than the surface area of the molded part; they should be between 30% and 70% of the surface area of the molded part. An SMC blank is placed in the mold in such a way that the flow paths to the edge of the molded part are equally long in all directions. The reproducibility of the insertion position and a consistent weight of the SMC blank are extremely important for quality.

As soon as the mold closes, the SMC board is deformed by pressure and heat. The moulding compound adapts completely to the tool contour. In practice, the mold temperatures range between 135 °C and 160 °C. The exact temperature depends on the mold contour and the SMC matrix used.

- The SMC supplied on rolls is cut into blanks.

- The SMC blanks are inserted into the preheated tool.

- Under pressure and temperature, the SMC blanks are formed into the contour in the press when the tool is closed.

- The finished molded part is deburred and released for further processing steps.

Advantages of Sheet Moulding Compound

The hot pressing process enables high reproducibility, short cycle times and high surface quality. In addition, the closed tool allows precise tolerances and complex geometries to be achieved – even with reinforcing ribs, inserts or metallic inserts. Another advantage is the low emission compared to open laminating.